Packaging Automation

Home »Increase Productivity With Automated Packaging Equipment

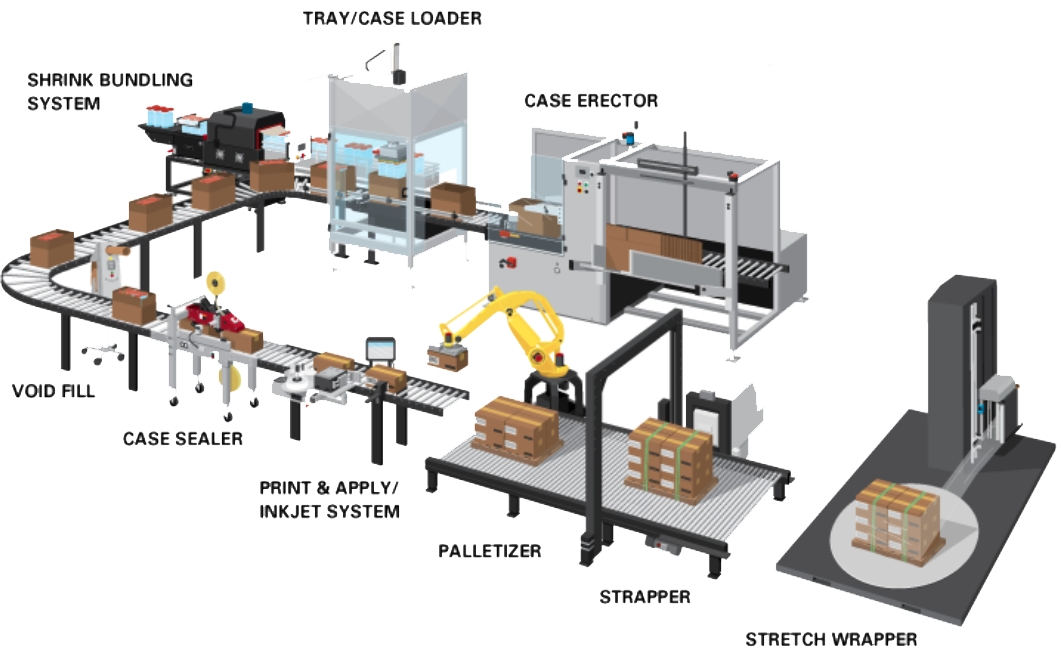

Many businesses rely on human capital to perform repetitive tasks like taping boxes, applying labels, and hand wrapping pallets. With packaging automation machinery, you will reduce labor costs and increase productivity. Simple and advanced automation can improve packaging quality and consistency and reduce material costs and waste. At New-Tech Packaging, we provide the support you need for the entire project, from automation offerings and performance testing to ROI data to support your investment.

New-Tech Packaging Automation Solutions

Recent Posts About Packaging Automation

New-Tech Packaging Automation Solutions

New-Tech Packaging Automation Solutions

Protective Packaging & Void Fill

Inflatable cushioning systems are easy to use, customizable, and effective. Depending on your packaging needs, you can produce air pillows or other inflatable films with an automated, on-demand cushioning system.

- Air pillows are great for product protection through the shipping cycle. Inflatable pillows are easy to use and are typically the most cost-effective solution for void fill.

- Inflatable bubble prevents products from migrating inside the box. These sheets, which can be wrapped around the product or layered into the package, are perfect for damage reduction for fragile items.

Air cushioning machines make pillows and cushions by feeding and guiding pre-made film through the system, inflating it, and sealing the inflation site so the air cannot escape. On-demand systems help reduce space needed for void fill and cushioning products on the warehouse floor.

Paper solutions and on-demand paper systems can be used to fill void in shipping cartons or can be coiled to cushion and used for blocking and bracing. Paper systems are easy to use, operator friendly, and effective. In paper void equipment, paper is fed directly into the equipment and then dispensed by the operator or at pre-determined lengths for void fill.

Automated Bagging System

Automated bagging systems provide a solution for getting your products packed and shipped in flexible packaging easily and quickly. The flexible packaging equipment, from semi-automatic machines to complete inline, fully automated packaging systems, provides a range of machinery with custom configurations and accessories to meet your needs. Goods are efficiently loaded, sealed, and ready to be shipped.

Our bagging systems can be customized to suit your processes, products, and organization.

- Available in a variety of sizes, from small, table-top style machines to large, fully automatic systems.

- Available in a variety of speed operation, from low to medium speeds for manual loading or higher speeds for automatic feeders.

- Options for top loading, side loading, or fully automatic with feeders.

- Capability to run on a wide variety of films including poly bags (low- and high-density polyethylene), retail bags (polypropylene), and specialty bags.

- Can be customized for direct inline printing with unique order information for each item.

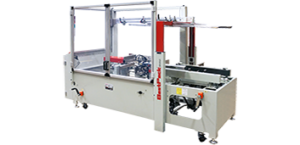

Case/Carton Erectors

Case erectors are an automated solution that forms cases for packaging products. Case handling equipment reduces the amount of labor needed to erect and seal cases, providing a reduction in labor costs and increase in productivity.

At New-Tech, we engineer the erector to match your operation. Erectors can be standalone or can integrate seamlessly with your existing packaging line. Customizations include ultra-compact systems, robotic options, sanitary washdown units for food industry, and high-speed erectors.

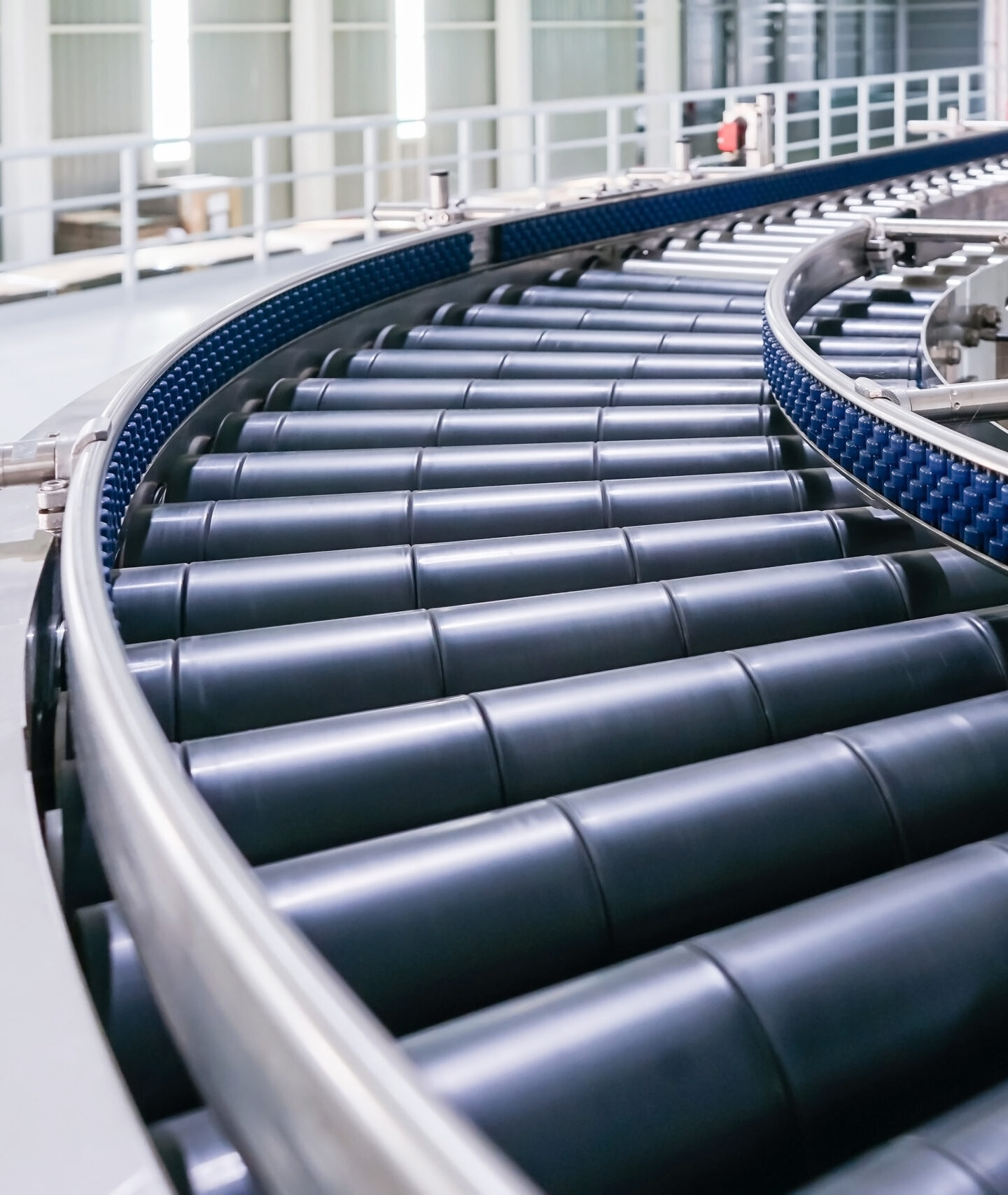

Conveyors

With a good conveyor line and layout, your packaging operation can run more efficiently with increased productivity. Conveyors allow for products to be streamlined to shipping locations while being worked on and/or packaged along the way.

Customizable Workstations

Customizable, ergonomic workstations are designed to improve employee comfort and increase productivity for employees who perform repetitive tasks like order fulfillment and packaging.

At New-Tech Packaging, we are proud to offer BOSTONtec and Dehnco workstations. These stations meet the American National Standards Institute/Human Factors Engineering guidelines for safety on the job. They are easily tilted, lifted, rotated, and stored for optimal flexibility and are customizable to meet the needs of the production or packaging line.

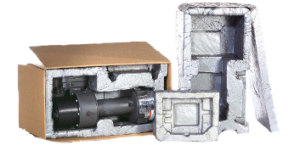

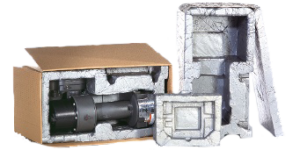

Foam-in-Place Systems

Foam-in-place systems automatically produce foam on demand to protect your product during the shipping cycle. These machines are simple to use, ideal for irregularly shaped and fragile items, and can even protect heavy, bulky products.

Foam-in-place polyurethane is molded in real-time by combining two liquid foams in a high-density polyethylene bag, film, or pre-fabricated mold. The mixture expands rapidly around the product, creating a custom protective shell.

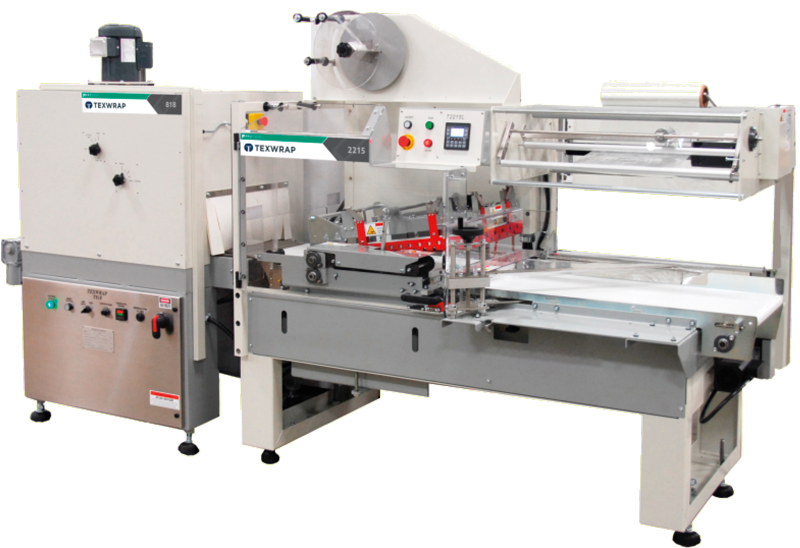

Shrink Bundling Machines

Shrink bundling machines allow you to automate enclosing, protecting, and even bundling your products in protective film. With automatic shrink wrapping and bundling, you can cut down on labor costs, prevent costly mistakes, and get products out the door faster.

Automatic shrink wrappers provide some unique benefits when compared to manual wrapping, including:

- More attractive and consistent packaging as well as greater seal strength, improving the overall package appearance.

- Lower material costs due to the ability to downgauge film and reduce the amount of film scrap.

- Reduced labor costs and higher throughput.

- Higher productivity with inline side-seal machines that have speeds of 60 to 100 packages per minute.

New-Tech also provides shrink tunnels, sleeve wrappers, and stretch sleeve machines.

Strapping Systems

Strapping systems provide both automatic and semi-automatic solutions that are designed to enhance efficiency for both steel and plastic strapping. There are several banding solutions available based on volume, throughput speed, and size of product banded. New-Tech offers hand-held battery tools, arch machines, bayonet machines, and fully automated systems designed to work in-line with your production flow.

Stretch Wrappers

New-Tech offers a full line of automatic and semi-automatic stretch wrap pallet packaging solutions. Replacing the manual application of hand film to a pallet with automation will increase the speed of wrapping, improve load unitization, and reduce the cost of stretch film. Stretch wrap equipment simply does a better job than people at consistently wrapping loads to wrap standards, decreasing the opportunity for damage during the ship cycle.

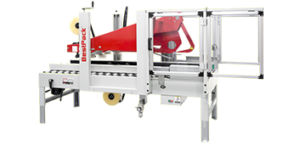

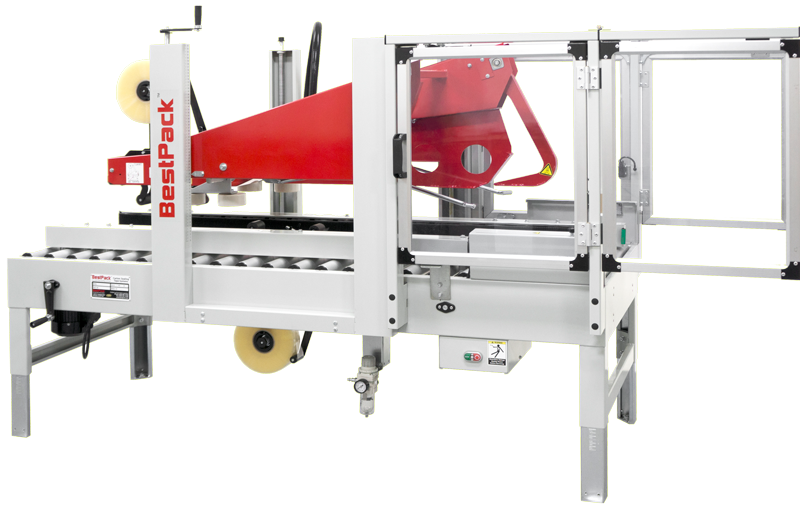

Tapers

Automatic tapers, or carton sealers, apply the correct amount of tape in an attractive application, reducing labor costs and material costs. In addition, carton sealers increase production and eliminate material waste. Selecting the proper carton sealer is important, taking into account:

- Size of the box

- Top and/or bottom sealer required

- Same size or different size boxes

- Type of tape applied

- Volume and throughput speed

Need Equipment Service and Repair?

We can do it! Your packaging machinery is vital to your operation. That is why it’s imperative to have a trusted service team ready for preventative maintenance, emergency repair, and regular repair services to keep your lines running. Our certified packaging equipment technicians are available to repair and service most types of packaging equipment.